① U-channel steel, as the basic stress component of the support and hanger, can be configured with various parts to form a complete structural support system.

② It is convenient for installation, maintenance and expansion of various pipelines, cable trays and equipment.

③ The optimized cross-section design determines the high bearing capacity of U-channel.

④ The tooth design of the inner edge of U-channel steel makes the connection between channel steel and spring nut safer.

⑤ It can be connected with wall, floor, ceiling and other structures.

⑥ A variety of instant noodles can be used in different environments.

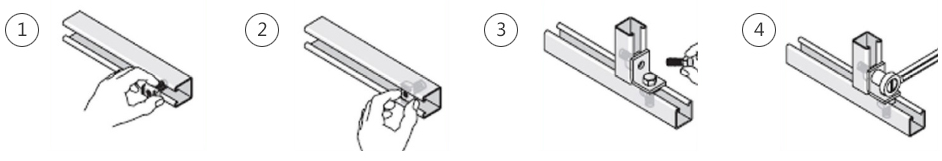

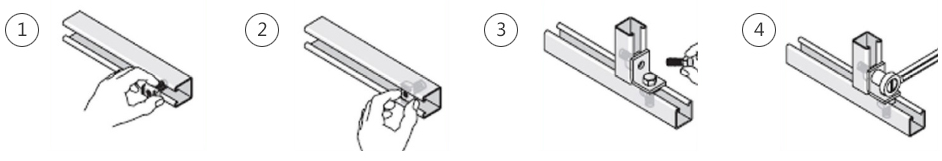

Installation:

① After the embedded spring nut is rotated 90 degrees, it moves along the groove body to fix the nut at the required position of the nut.

② Install the connection piece.

③ Connect other components.

④ According to the installation torque of spring nut, tighten the bolt.