Construction technology and quality control process of finished supports and hangers, fabricated supports and hangers and comprehensive supports and hangers

1) Accurate cutting

(1) According to the bracket design node diagram, select parts.

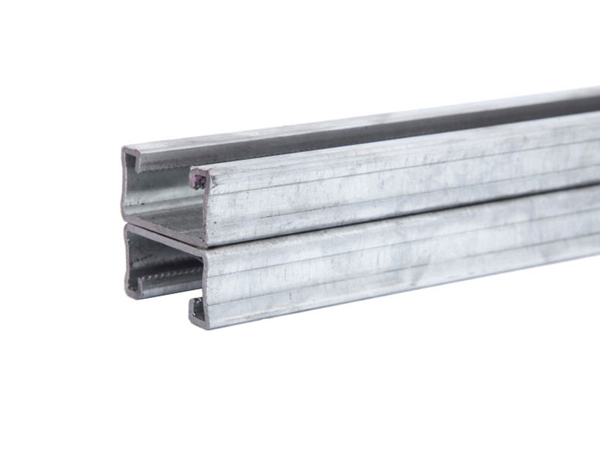

(2) Cutting channel steel

Notes: ① select the correct type of spare parts according to the design drawings; ② when cutting the channel steel, the cutting must be accurate according to the scale shown on the channel steel, and the cutting surface is required to be vertical and smooth.

2) Fixing of supports and hangers

(1) Installation of anchor bolt

① BZ 12-20 / 115 anti shock expansion screw anchor bolt is selected

② Mark out the installation position of anchor bolt on the concrete beam or floor, and use electric tools to drill the hole with the diameter of 12mm and the drilling depth of 115mm.

③ Hole cleaning

④ Install the anchor bolt

⑤ The tightening torque is 45nm.

(2) Mounting bracket base

(3) Vertical channel steel installation

(4) Installation of cross bar

Note: on the concrete structure, when the expansion anchor bolt is used to fix the support and hanger, the insertion of the expansion anchor bolt must reach the specified depth value; when BZ anchor bolt is used, it must be installed with special tools and meet the installation standard required by BZ anchor bolt. Installation equipment: electric hammer drill, drill bit, blowing pump, torque wrench, hexagon socket of appropriate size.

(5) Height adjustment

According to the position of the pipeline, align the elevation center and horizontal center, and adjust the height of the cross arm.

Note: the fixed support of the pipeline should be installed in strict accordance with the design drawings. If the installation cannot be carried out due to the site conditions, the designer of the design institute should be consulted to modify the design of the pipe support; the hanger should be installed according to the construction drawing, and the suspender should not be bent or deformed; the support spacing should be set correctly according to the design requirements; the support and hanger installation should be carried out simultaneously with the pipeline installation; after the construction, the pipe support should be installed at the same time Wipe the bracket clean and cover all exposed channel ends.

3) Installation of tube bundle

(1) Installation of tube bundle gasket or sliding support

(2) Tube bundle installation

Note: when installing the pipe support or its parts of the sliding support, the thermal displacement of the pipeline should be considered. Generally, the pipeline should be offset by a certain distance in the opposite direction of the pipeline expansion, and the offset value is 1 / 2 of the total thermal displacement at this place. The sliding surface of the guide support and the sliding support should be clean and flat, and the ball, roller, roller and other moving parts should be in good contact with their supporting parts, so as to ensure the free expansion of the pipeline All movable parts of the movable support shall be exposed and shall not be covered by thermal insulation layer.

4) Inspection and adjustment of supports and hangers

(1) Adjustment of pipe support with thermal displacement

The following inspection and adjustment shall be carried out for the supports and hangers in time when the pipes with thermal displacement are subject to thermal expansion.

a: Whether the displacement direction, displacement and guiding performance of the movable support meet the design requirements.

b: Whether the pipe bracket falls off.

c: Whether the fixed support is firm and reliable.

(2) Adjustment of constant force support and hanger

The constant force support and hanger shall be installed and adjusted according to the design requirements.