seismic supports and hangers are the facilities produced according to the compulsory provision 3.7.1 in code for seismic design of buildings (2008 Edition) of GB 50011-2001: "non structural components, including non structural components of buildings and auxiliary mechanical and electrical equipment of buildings, and their connection with the main structure shall be subject to seismic design". Seismic support and hanger is a new thing in China, but it has a long history in foreign countries, especially in the developed countries with frequent earthquakes.

The mechanical and electrical anti-seismic support and hanger system is a support system which is firmly connected with the pipeline, groove system and equipment of the building structure which has been made seismic design. The original general support and hanger system is the support system with gravity as the main load. The settings of these two support systems are not repeated, but complementary. Huang Qiaojun, from the Institute of architecture, Chenggong University, Taiwan, simulated the spray pipeline of a parking lot in Puli Town, Nantou County with the shaking table of an earthquake test rig. The conclusion is that the displacement of each point of the pipeline with anti-seismic support system is 5-10 times lower than that without seismic support, which effectively improves the seismic performance of the pipeline system

1、 Layout principle of pipeline seismic system

The lateral spacing requirements of pipeline anti-seismic reinforcement are as follows: for pipelines with groove connection, welded steel pipe, brazed copper pipe and other rigid materials, the maximum distance between horizontal hangers shall not exceed 12m; for pipelines with non rigid materials such as HDPE, the maximum distance between horizontal hangers shall not exceed 6m.

The longitudinal spacing requirements of pipeline anti-seismic reinforcement are as follows: for pipelines with groove connection, welded steel pipe, brazed copper pipe and other rigid materials, the maximum distance between longitudinal hangers shall not exceed 24m; for pipelines with non rigid materials such as HDPE, the maximum spacing between horizontal hangers shall not exceed 12m.

2、 Layout principle of duct seismic system

The maximum distance between the lateral seismic hangers of ordinary rigid duct is 9m, and the maximum spacing of longitudinal seismic hanger of ordinary rigid duct is 18m.

The maximum spacing of lateral seismic hangers for fiberglass, plastic and other non rigid duct materials is 4.5m and the maximum longitudinal spacing is 9m.

3、 Layout principle of electrical seismic system

The maximum lateral seismic spacing of rigid electrical conduit, trunking and cable tray shall not exceed 12M, and the maximum longitudinal seismic spacing shall not exceed 24m.

The maximum space between the cable tray and the non seismic cable tray shall not exceed 6m.

4、 Seismic calculation principle

The installation form and layout principle of the anti-seismic support and hanger system are determined according to the strict mechanical calculation results, and the calculation of seismic force must meet the requirements of the code

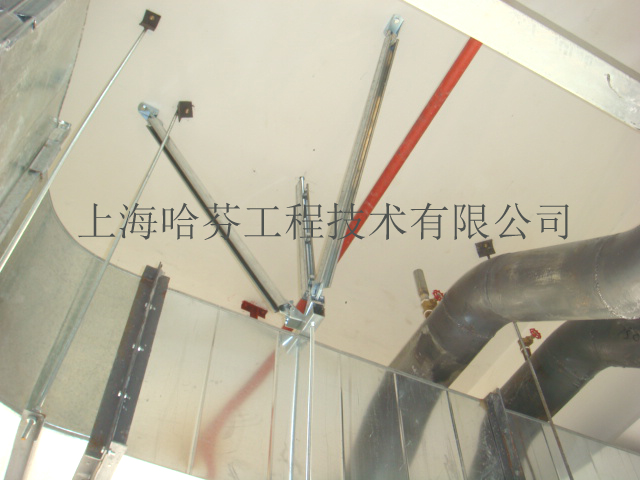

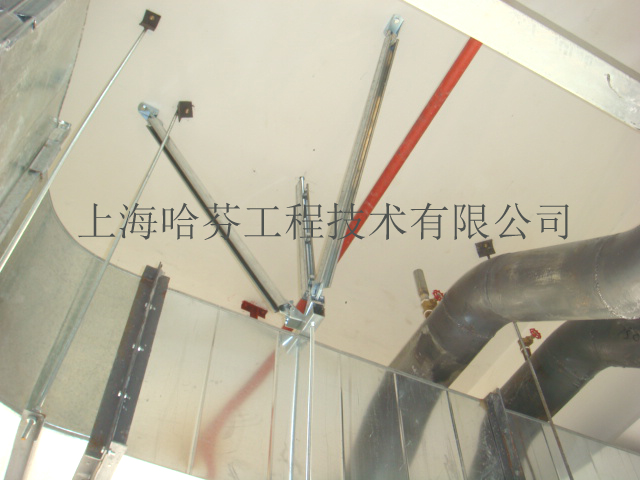

5、 Construction technology of seismic support and hanger

The seismic support is composed of anchor solid, reinforced suspender, diagonal brace and seismic connection components. The distance between the node between the suspension screw and the pipeline and the node between the diagonal brace and the pipeline shall not exceed 0.1M, and the screw shall be reinforced as required. If two opposite rigid seismic supports are set up at the same position, the suspension screw can be omitted. Considering the seismic load, the size of the suspension screw and the structural anchorage of the rigid seismic support should be increased, and the maximum bearing capacity of the screw and anchor should be greater than the calculated seismic force.

Construction basis of seismic support and hanger

Seismic support and hanger can provide sufficient protection for water supply and drainage system, air conditioning system and electrical pipeline system in earthquake, so seismic support and hanger must be greater than seismic force at any time and at any installation angle. The horizontal seismic load can be borne by two seismic braces in different directions, that is, the lateral seismic support bears the lateral load, and the longitudinal seismic support bears the longitudinal load. All seismic supports must be reliably connected with the structure. Rigid connection with beam column slab of reinforced concrete frame structure and flexible connection with steel structure must be checked by designers.

Construction steps of seismic support and hanger: measurement → blanking → installation of expansion bolt (or screw blasting) at lifting point → vertical suspender installation → cross arm (or pipe clamp) installation → lateral and longitudinal reinforcement installation

6、 Construction technology of 2.4 seismic support and hanger in mechanical and electrical installation engineering in June 2010

(1) The longitudinal deviation of pipe and wire sleeve is allowed, but it shall not exceed 1 / 16 of the maximum lateral support distance; the deviation of air duct is allowed, but it shall not exceed 2 times of the width of air duct.

(2) When the horizontal pipeline turns at 90 degrees, seismic supports and hangers are required; when the turning length of other angles is greater than 1 / 16 of the seismic design spacing, lateral and longitudinal seismic supports and hangers are required.

(3) When calculating the horizontal seismic load, only the full load weight should be considered, and no other factors should be considered.

(4) The seismic hanger should not limit the stress caused by the thermal expansion and cold contraction of the pipeline. When considering the thermal expansion and cold contraction factors, the longitudinal hanger should be considered in the component selection, and the selected model should be able to resist the thermal expansion and cold contraction stress of the pipeline.

(5) The seismic hanger pipe code of thermal insulation pipeline should be considered according to the size after insulation. The portal hanger is used for thermal insulation air duct, and the water pipe is also considered.

(6) The rigid pipeline seismic support can not be installed in different structural parts or functional parts of the building, otherwise different displacement will be produced due to earthquake action.

(7) The single pipe seismic support with two-way lateral or longitudinal or inflection point seismic support with lateral / longitudinal action shall be directly connected with pipeline or wire sleeve. It should be noted that the support of branch pipe or small first class pipeline can not be used as seismic support of main pipe, that is, it can not be used as the support of other direction (main pipe).

(8) The design of settlement displacement should be considered when the pipeline passes through the building settlement joint.

(9) The best vertical angle of side / longitudinal diagonal brace installation is 45 ° and can be adjusted according to the actual situation on site.

(10) For single pipe or multi pipe common door type hanger of water, electricity and wind system, the bearing capacity will not be affected when the diagonal brace deviates from the center line by 2.5 ° regardless of the lateral or longitudinal diagonal bracing