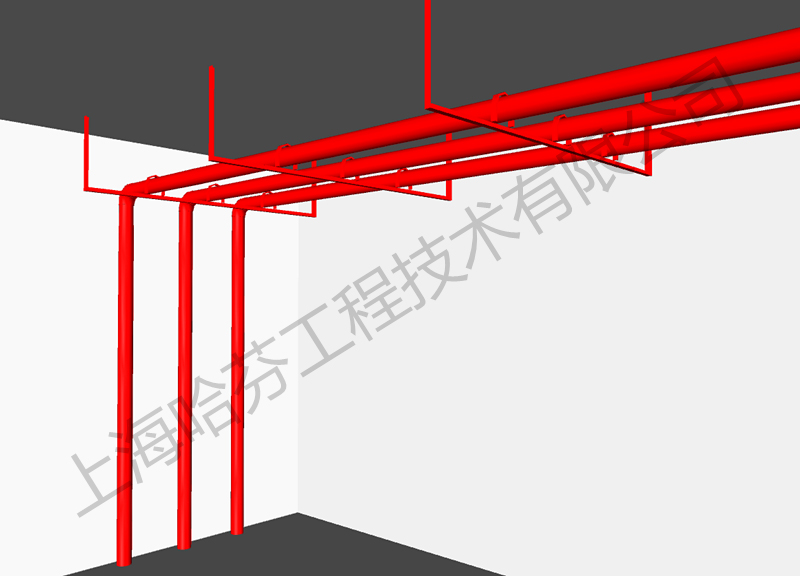

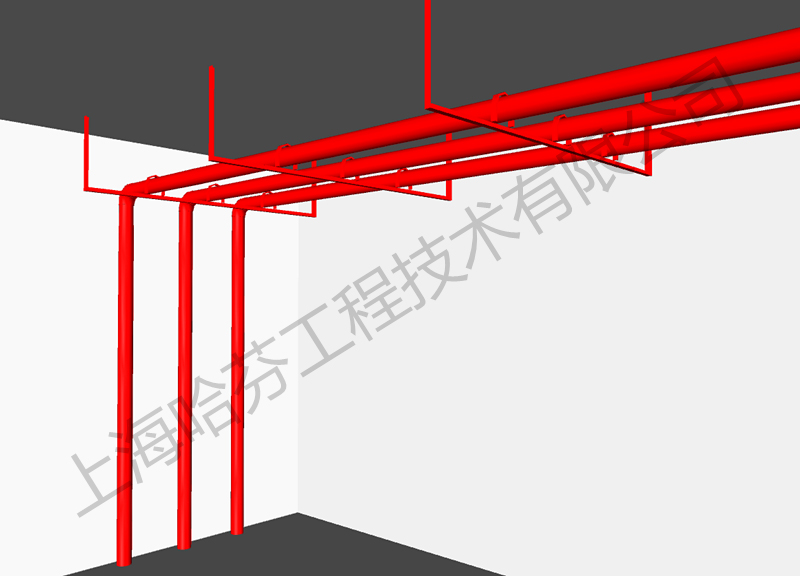

The combined support and hanger, that is, the fabricated pipeline support and hanger system, is composed of channel steel system, fittings system, tube bundle system and so on, which are connected mechanically by bolts. The height and size of the pipe can be adjusted at will. The frame of hanger system of integrated pipeline is a rigid support composed of one or more channel steel; the combined support and hanger is generally divided into single-layer or multi-layer system according to the number of installation layers of pipeline, and has the function of field adjustment and modification, which is more conducive to the space utilization of pipeline layout. According to the number and characteristics of the pipeline on site, the beam (bracket) can adjust the elevation or position according to the actual situation of the site, and can expand the system according to the later system operation requirements. It has various technical indexes such as impact resistance, fire prevention, corrosion prevention and so on.

The comprehensive layout and installation of equipment, air duct, cable tray and various kinds of pipes in large-scale indoor engineering often affect the construction progress and appearance of itself and related specialties, and the selection and installation of supports and hangers are the premise conditions to determine whether the comprehensive layout of equipment and pipelines is reasonable and beautiful. Through the optimization design and installation of indoor supports and hangers in building installation engineering according to local conditions, the installation of equipment, air duct, cable tray and various pipelines can achieve the effect of material saving, compact and beautiful layout, solid and reliable quality, and provide favorable conditions for the layout of comprehensive pipe, It also saves the construction period for the construction of building installation engineering, and produces certain social benefits.

This technology is suitable for the narrow places with various pipelines and limited layout space. Especially for the corridor of construction engineering

Where pipelines are concentrated such as basement and corridor. As an important part of the building structure, the basement has a wide range of equipment and complex pipelines, which has great inconvenience in construction and maintenance, especially in the pump room and fan room. Therefore, it is an important problem to solve the dense pipeline layout in the basement electromechanical construction.

1. Main characteristics and composition of fabricated pipe supports and hangers

1.1.1 the construction is simple. Because the same support and hanger can be used for air conditioning water system, air conditioning air system, fire control leveling main pipe and strong and weak current bridge, the supports have been arranged and installed before construction. The complex process of interspersed installation of supports and hangers is eliminated, and the work efficiency is improved.

1.1.2 save investment. The amount of steel support and hanger is reduced and the cost is reduced.

1.1.3 effective control of elevation. Comprehensive horizontal technology is how to effectively use the space, under the premise of meeting various pipeline layout, compressing space can effectively control the elevation.

1.1.4 the pipeline layout can be clear. Reduce the number of supports and hangers, and arrange the comprehensive supports and hangers evenly and reasonably, so that the pipeline looks clear and has no sense of disorder.

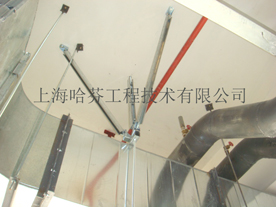

1.1.5 pipe supports and hangers shall be assembled without welding and mechanical drilling on site, and can be adjusted and reused at will.

1.1.6 the use of pipe supports and hangers can standardize the pipeline layout of various specialties and reduce the coordination of quality inspection sheets of various specialties.

1.1.7 pipe supports and hangers are composed of finished parts. The size and height of pipe support can be adjusted arbitrarily by mechanical connection between the assembly and spring nut or lock lock. Supports and hangers are not welded on site, and are reliably connected with concrete structure by sleeve expansion bolts.

2. Problems in application

The fabricated pipe supports and hangers have many advantages, but some deficiencies are also exposed in the actual engineering. For example, the products mainly rely on the technical requirements of the manufacturer to inspect the quality of the products, and there is a lack of standard and detailed construction acceptance specifications; the installation and fixation are not in place and not standardized in the installation process, which leads to the deformation of the supports and hangers.

3. Installation acceptance

The construction process should be reasonably arranged on the premise of safety. As there are many pipelines and long suspenders on the comprehensive supports and hangers, it is forbidden to install and test the pipelines before the bearing system of the comprehensive pipeline supports and hangers has not been formed. Before pipeline installation, pull-out test shall be conducted for expansion bolt, and the test requirements shall meet relevant requirements of technical specification. When the expansion bolt takes root in the structural concrete of the fixed support and hanger, the bolt installation must reach the specified depth value.

4. Application of BIM Technology

The feature of BIM Technology is "what you see is what you get", so it can solve the problem of pipeline collision in advance, reduce the conflict of field construction, reduce the construction change, and bring convenience for the mechanical and electrical construction. The use of combined supports and hangers can save materials and arrange pipes reasonably. However, when the design institute drew the drawings, each specialty drew separately, and did not consider the use of combined crane support during construction. In the field construction, the workers need to set up the combined supports and hangers according to the site conditions, and also need to adjust the sizes of various supports and hangers according to the situation. Without the guidance of drawings, the site construction is not convenient enough.

Through the foresight of BIM Technology, in the pipeline design process, the conscious design and use of composite supports and hangers can be very convenient to guide the site construction. Through the drawing of BIM Technology, the workers can quickly set the pipeline direction, elevation, support and hanger position. Because of the collision inspection during design, it is possible for all specialties to construct at the same time. Combined supports and hangers can be installed in advance before pipeline layout, which can effectively save labor and materials.